Tensile strength

Type of resources

Available actions

Topics

Keywords

Contact for the resource

Provided by

Years

Formats

Representation types

Update frequencies

-

The dataset contains indirect tensile strength data of salt samples collected from the Northwich Halite Member at the Winsford Mine in Cheshire, UK. Each sample was unconfined and deformed under uniaxial compression, where the primary principal stress corresponds to the axial stress and the intermediate and minimum principal stresses are equal to 0. Each sample was deformed using a constant loading rate of 200 N/s. The tests were completed using a servo-controlled stiff load frame equipped with an indirect tension fixture in the Rock Mechanics and Physics Laboratory at the British Geological Survey, Keyworth UK. The data are separated into individual Microsoft Excel files, with each file representing a single test. Each file contains time, axial force, axial displacement, and tensile stress data.

-

Geomechanical strength data of mudstone samples collected from the Gunthorpe Member, of the Sidmouth Mudstone Formation of the Mercia Mudstone Group. Testing includes Uniaxial Compressive Strength (UCS), Indirect Tensile Strength (ITS) and Triaxial strength testing completed at the University of Leeds (UoL) and Point Load testing and thermal loading testing completed at the British Geological Survey (BGS). All sample preparation, preservation and testing were completed to the specification outlined by the ISRM (2007) unless otherwise stated. For all Triaxial testing, each sample was deformed under standard triaxial stress conditions, where the primary principal stress corresponds to the axial stress and the intermediate and minimum principal stresses are equal to that of the confining pressure. The data are separated into individual Excel files (.xlsx), with each file representing a single test. Each file contains time, force, stress, displacement, and strain data.

-

Geomechanical strength data of mudstone samples collected from the Grey Shale Member, of the Whitby Mudstone Formation of the Lias Group. Testing includes Uniaxial Compressive Strength (UCS), Indirect Tensile Strength (ITS) and Triaxial strength testing completed at the University of Leeds (UoL) and Point Load testing completed at the British Geological Survey (BGS). All sample preparation, preservation and testing were completed to the specification outlined by the ISRM (2007) unless otherwise stated. For all Triaxial testing, each sample was deformed under standard triaxial stress conditions, where the primary principal stress corresponds to the axial stress and the intermediate and minimum principal stresses are equal to that of the confining pressure. The data are separated into individual Excel files (.xlsx), with each file representing a single test. Each file contains time, force, stress, displacement, and strain data.

-

Geomechanical strength data of mudstone samples collected from the Grey Shale Member of the Whitby Mudstone Formation of the Lias Group. Testing includes cyclic thermo-mechanical loading completed at the British Geological Survey (BGS). All sample preparation, preservation and testing were completed to the specification outlined by the ISRM (ISRM, 1978b; ISRM, 1978a; Bieniawski and Bernede, 1979; ISRM, 1985 for determining the indirect tensile strength, triaxial strength, UCS and point load strength respectively) unless otherwise stated. Each test was comprised of three main stages: 1) A heating stage where the sample is heated to a set temperature loading scheme under pressure conditions of 1-1.4 MPa axial stress and 0.5 MPa confining pressure throughout the heating stage 2) A preloading stage, where the confining pressure is increased to 5 MPa which was held throughout the triaxial compression test. 3) Triaxial compression test, during the active deformation phase, the samples were axially loaded using a constant displacement rate of 0.0012 mm s-1. The data are separated into individual Microsoft Excel files, with each file representing a single test. Each file contains time, force, stress, displacement, and strain data.

-

Geomechanical strength data of mudstone samples collected from the Gunthorpe Member, of the Sidmouth Mudstone Formation of the Mercia Mudstone Group. The testing was completed at the British Geological Survey (BGS). All sample preparation, preservation and testing were completed to the specification outlined by the ISRM (ISRM, 1978b; ISRM, 1978a; Bieniawski and Bernede, 1979; ISRM, 1985 for determining the indirect tensile strength, triaxial strength, UCS and point load strength respectively) unless otherwise stated. Each test was comprised of three main stages: 1) A heating stage where the sample is heated to a set temperature loading scheme under pressure conditions of 1-1.4 MPa axial stress and 0.5 MPa confining pressure throughout the heating stage 2) A preloading stage, where the confining pressure is increased to 5 MPa which was held throughout the triaxial compression test. 3) Triaxial compression test, during the active deformation phase, the samples were axially loaded using a constant displacement rate of 0.0012 mm s-1. The data are separated into individual Microsoft Excel files, with each file representing a single test. Each file contains time, force, stress, displacement, and strain data. The data are separated into individual Excel files (.xlsx), with each file representing a single test. Each file contains time, force, stress, displacement, and strain data.

-

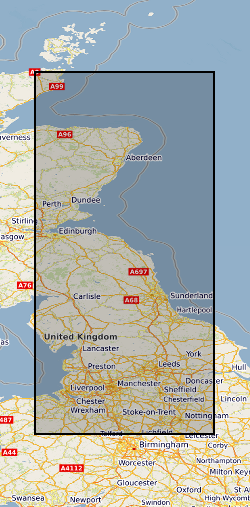

This datasets contains 323 observations of borehole breakouts across and drilling induced tensile fractures from borehole imaging used to re-characterise the UK stress field orientation in 2016. This was published in the Journal of Marine and Petroleum Geology and is openly available using doi:10.1016/j.marpetgeo.2016.02.012 The observations relate to 39 wells from Central England, Northern England and Northern Scotland and are provided with links to screen grabs of the images for clarity. The basic well metadata is supplied along with a description of the dataset. The Images were generated in the IMAGE DISPLAY module of the Landmark RECALL software and are supplied on an “as shown” basis. Descriptions of the tools and the techniques used are listed in the accompanying paper: KINGDON, A., FELLGETT, M. W. & WILLIAMS, J. D. O. 2016. Use of borehole imaging to improve understanding of the in-situ stress orientation of Central and Northern England and its implications for unconventional hydrocarbon resources. Marine and Petroleum Geology, 73, 1-20.

-

A brief description of ten core plug samples collected from borehole GGC01 (Glasgow, United Kingdom) is provided, as well as for twelve 15-50 g cuttings samples from 1m intervals within borehole GGA08. Samples were also collected from borehole GGA02 but not used for further analyses. Data comprise results from geomechanical tests, permeability and porosity measurements, and X-Ray Diffraction analyses performed on drillcore samples of sandstones, siltstones, mudstones and coals from eleven depth intervals within the GGC01 borehole. Geomechanical data include triaxial compressional strength, tensile strength, and frictional strength. Frictional strength data was also collected for cuttings samples of sandstones, siltstones, mudstones and coals from the GGA08 borehole. In total twenty-three tensile strength tests were performed on ten sampled intervals, and seven porosity measurements pre-and post-failure were taken. Nine triaxial compressive strength tests and twenty-one frictional strength tests were performed, with permeability measured both before and after failure or shear respectively. From compressive strength tests we also determined the Young’s modulus and Poisson’s ratio. Samples and data are derived from the UK Geoenergy Observatories Programme funded by the UKRI Natural Environment Research Council and delivered by the British Geological Survey.

-

The dataset contains unconfined compressive strength data of salt samples collected from the Northwich Halite Member at the Winsford Mine in Cheshire, UK. Each sample was unconfined and deformed under standard uniaxial stress conditions, where the primary principal stress corresponds to the axial stress and the intermediate and minimum principal stresses are equal to 0. Each sample was axially compressed using either a constant strain rate of 1e-5 per second or a constant loading rate of 200 N/s. The tests were completed using a servo-controlled stiff load frame in the Rock Mechanics and Physics Laboratory at the British Geological Survey, Keyworth UK. The data are separated into individual Microsoft Excel files, with each file representing a single test. Each file contains time, force, stress, displacement, and strain data.

-

This work presents a detailed three-dimensional finite element based model for wave propagation, combined with a postprocessing procedure to determine the fracture intensity caused by blasting. The data generated during this project includes output files of all simulations with detailed fields, geometries and meshes. The model incorporates the Johnson-Holmquist-2 constitutive model, which is designed for brittle materials undergoing high strain rates and high pressures and fracturing, and a tensile failure model. Material heterogeneity is introduced into the model through variation of the material properties at the element level, ensuring jumps in strain. The algorithm for the combined Johnson-Holmquist-2 and tensile failure model is presented and is demonstrated to be energy-conserving, with an open-source MATLABTM implementation of the model. A range of sub-scale numerical experiments are performed to validate the modelling and postprocessing procedures, and a range of materials, explosive waves and geometries are considered to demonstrate the model's predictive capability quantitatively and qualitatively for fracture intensity. Fracture intensities on 2D planes and 3D volumes are presented. The mesh dependence of the method is explored, demonstrating that mesh density changes maintain similar results and improve with increasing mesh quality. Damage patterns in simulations are self-organising, forming thin, planar, fracture-like structures that closely match the observed fractures in the experiments. The presented model is an advancement in realism for continuum modelling of blasts as it enables fully three-dimensional wave interaction, handles damage due to both compression and tension, and relies only on measurable material properties. The uploaded data are the specific simulation outputs for four explosion models occurring on two different rock types, and the specific fracture patterns generated.

-

UKGEOS and Core Sample Analysis. Geomechanical testing was performed to determine triaxial compressional strength, tensile strength, frictional strength and permeability of sandstones, siltstones, mudstones and coals from eleven depth intervals within the GGC01 borehole, UK Geoenergy Observatories (UKGEOS), Glasgow, United Kingdom. Frictional strength tests were also performed on cuttings samples of sandstones, siltstones, mudstones and coals from the GGA08 borehole, Glasgow, United Kingdom. In total twenty-three tensile strength tests were performed on ten sampled intervals, and seven porosity measurements pre-and post-failure were taken. Nine triaxial compressive strength tests and twenty-one frictional strength tests were performed, with permeability measured both before and after failure or shear respectively. From compressive strength tests we also determined the Young’s modulus and Poisson’s ratio. Results of X-Ray Diffraction are also included in the dataset.

NERC Data Catalogue Service

NERC Data Catalogue Service